SAN/NAS/Object/Tape/Hyperconverged/Converged/On Premise/Hybrid/Cloud/Edge

What do all of these technologies have in common?

They all run on hardware that draws power and generates heat. The newest, fastest versions draw more power and generate more heat. So, why not place them in an environment that will keep them running efficiently? Why not be alerted when a problem arises?

Top Tier Data Centers get it, and they do. Why aren’t we protecting our data to the level they do? Expense? Sure. Or do we need to protect our data to the level they do? Probably not. Is there an approach that will improve our environments to limit downtime without breaking the budget? Or more clearly the expense versus the probability that a major failure will occur.

A friend of ours has a great story about when a former company (unnamed to protect the guilty ☺) had a catastrophic failure of their SAN when the air conditioning broke down in the middle of the night and all data was lost. He was asked to develop a plan to prevent it from happening again. He came back with the plan and budget. When the CEO looked at the numbers, said “Wow that’s way too expensive and what are the odds this could happen again anyway?” I think you know what happened next.

What can we in Postproduction and Broadcast do to protect our machine rooms that are actually mini–data centers? Are there levels of protection and environment monitoring with alerts that can meet the expense versus risk criteria?

So, what are some of the types of products/solutions and best practices we can use to minimize downtime without breaking the bank?

Obviously clean power and enough air conditioning. A floor standing cooling unit and UPS for larger rooms and at least rack mounted UPS units in the individual racks. For locations where comfort cooling is the only source or if the servers are located in a small space or closet, this is a big deal.

In-Rack/In-Row Cooling

In-rack cooling and in-row cooling are a solution. Below are two solutions from Vertiv/Liebert. On the left is a self-contained rack with built in air conditioning, rated for 3 KVA and just needs power and a place to vent the hot air, usually into a plenum or out a window. On the right is an in-row cooling system which is similar but requires a condenser mounted outside the room. I use these Vertiv products as examples, other companies have solutions too.

Vertiv/Liebert VCR-S In-Rack Cooling

Vertiv/Liebert VCR-S In-Rack Cooling Vertiv/Liebert CRV In-Row Cooling

Vertiv/Liebert CRV In-Row CoolingEnvironmental Monitoring

In order to ensure equipment is kept at a safe operating temperature and humidity range, in-rack environmental sensors connected to intelligent power strips (iPDU’s) or a smart rack controller system can be deployed. On the left is a Lagrange/Raritan Smart Rack Controller capable of daisy chaining various types of environment sensors shown on the right. These sensors can be mounted on the bottom middle or top of the racks depending on how precise you want to track temperature and humidity. There are other sensors too such as door locks, water detection and air flow. IMHO, bare minimum is one temperature sensor in each rack. The data from the sensors can be tracked by a web browser or connected to DCIM (Data Center Infrastructure Management) or other software programs.

Raritan SRC

Raritan Environmental Sensors

Raritan Environmental SensorsPDU’s — Simple to Complex

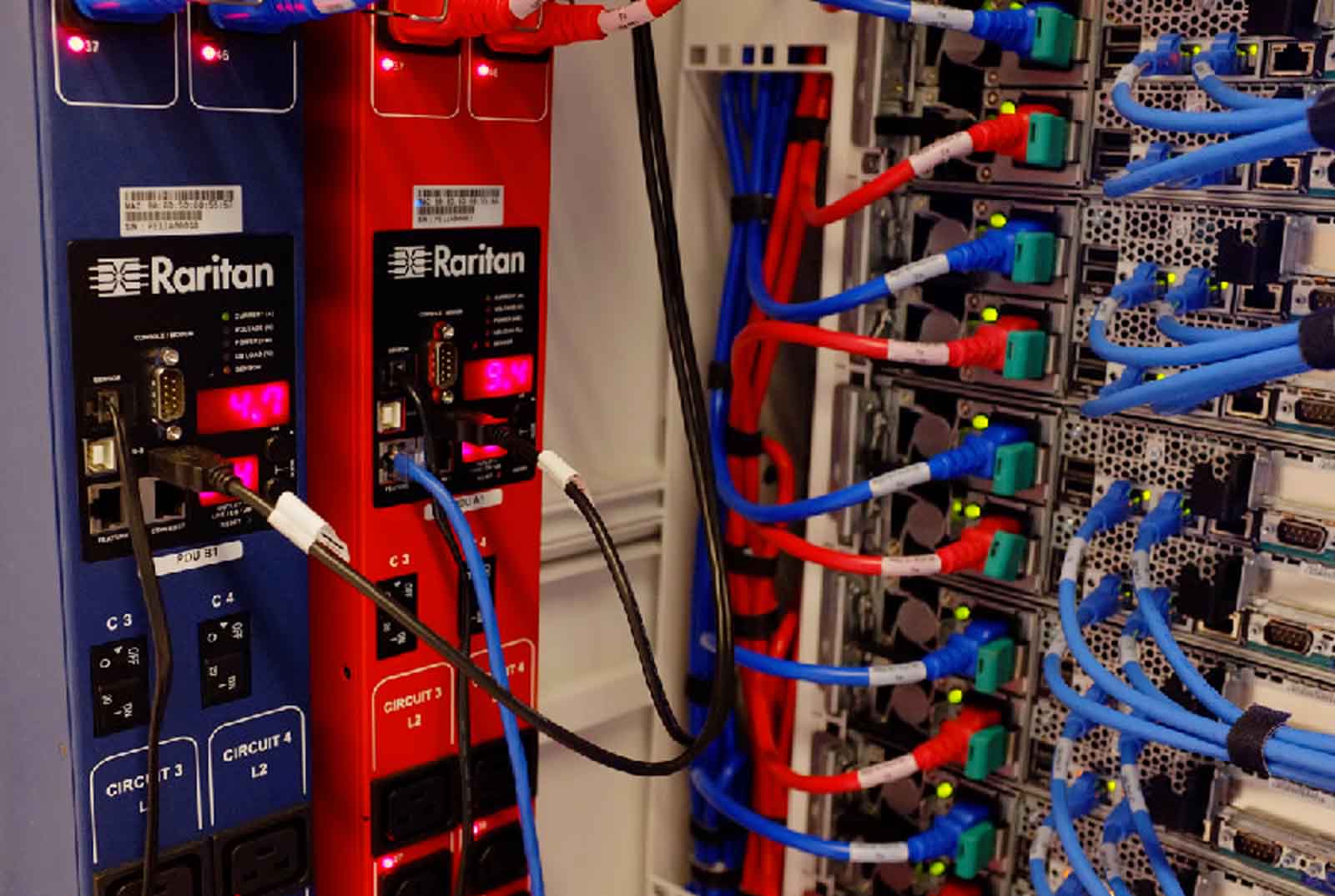

Another solution to environment monitoring is connecting the sensors to iPDU’s which are intelligent power strips in each rack. PDU’s come in various sizes and features from simple power strips to complex iPDU’s. An added bonus is these iPDU’s can monitor power to the rack, power draw in each outlet and the more complex iPDU’s can cycle power on and off to each outlet. The high-end iPDU’s provide the ability to monitor from a browser or provide API’s to connect with other software products like DCIM. Below are some examples from Raritan, Chatsworth and ServerTech.

Raritan iPDU’s

Chatsworth Environmental Monitoring

Chatsworth Environmental Monitoring Servertech iPDU’s

Servertech iPDU’sDCIM Software

DCIM is the acronym for Data Center Infrastructure Management and is the marriage of Information Technology and Data Center Facility Management disciplines. There are many levels of DCIM that range from Ad-Hoc Reactive to Proactive to Self-Regulating and Intuitive.

The core elements of DCIM are:

- Power Management and Monitoring

- Environmental Management and Monitoring

- Mapping and Planning

- Capacity and Change Management

- Asset Management

- Process Management

- Access and Control

There are versions by many different manufacturers from simple to complex. Broadcast and Postproduction machine rooms may not need all of the features above, but power and environmental management and monitoring is highly recommended.

An example of a powerful but a simple DCIM solution is Power IQ and DC Track from Sunbird. Part of the dashboard is shown below and a 3D map of a large machine room.

Along with proper air, power, environmental monitoring with emergency alerts, having a proper documented facility along with easily readable cable labels with wire numbers is a must.

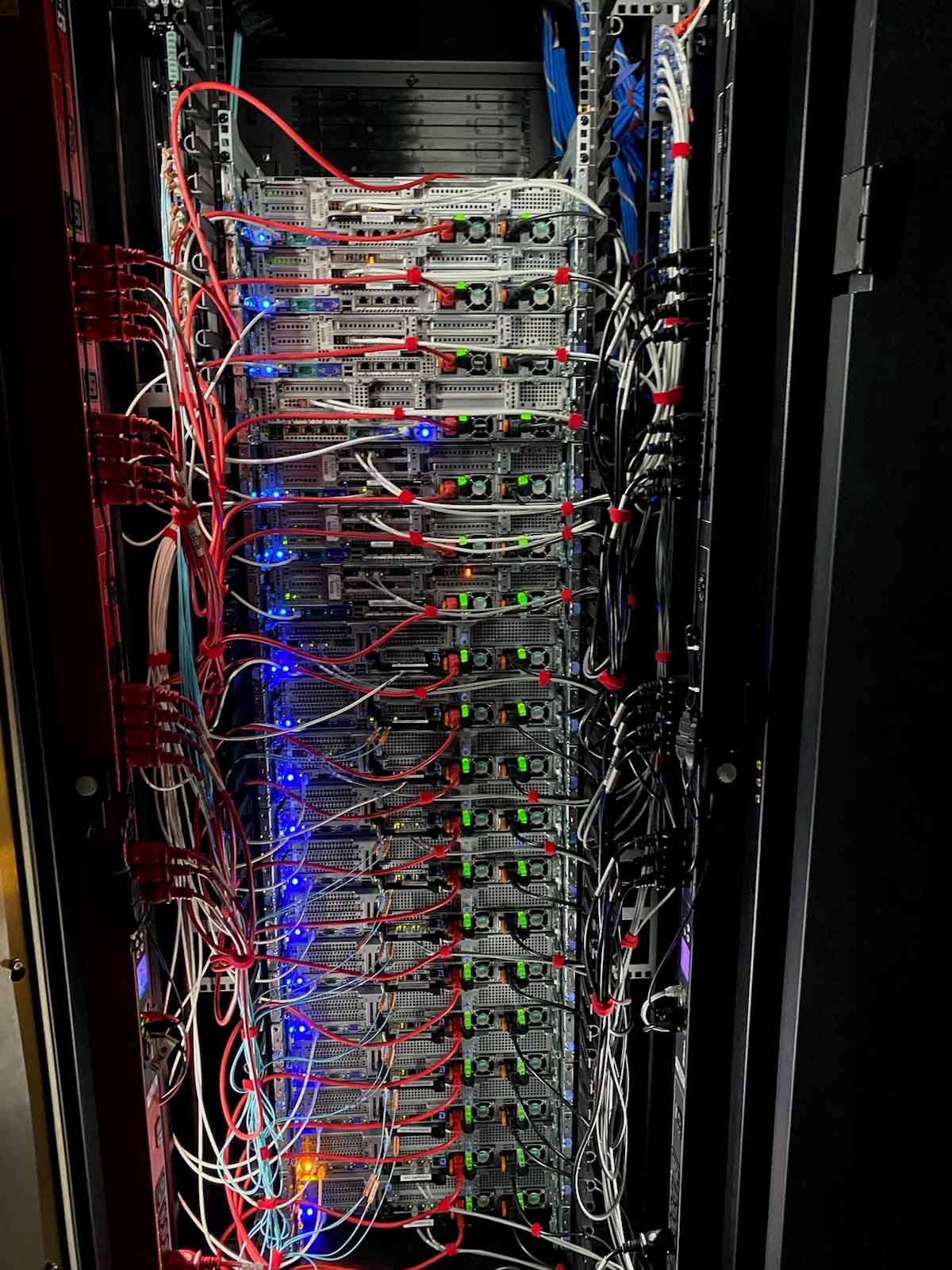

On the subject of reading cable labels, how many times have you tried to find a cable in the back of a dark rack with a flashlight or drop light? Here’s an example of an inexpensive in-rack lighting solution that fully illuminates the rack when the door is opened and goes back off when the rack door is closed. There are two bright LED strips that magnetically mount anywhere in the rack and are powered by a USB connection.

Sentieris Rack Light System Model SE-PRL-101

Sentieris Rack Light System Model SE-PRL-101 Inside of rack fully illuminates when rear door is open

Inside of rack fully illuminates when rear door is openAs we know, machine rooms are really data centers and there are lots of inexpensive solutions to ensure equipment functions in a safe environment with minimal downtime.

No Comments